Micarta Sliders

I offered a few Micarta sliders at the start of the year (I think it was exactly four if I recall).

They were very popular and I have been asked a lot for more Micarta since then.

Finally... I got hold of some Micarta and we're making some more sliders with this material:

As far as I understand this Micarta is from the 90s. It's not super-old - but it's still old.

I have enough for somewhere between 8 and 12 sliders at most right now. I am going to order more as soon as I can though.

The first few will be dropped today.

New Stuff Coming Up...

Here's a short video on some NEW things coming soon:

Prototype Mini-Atom (behind the scenes)

The Atom is one of our most popular products right now (based on how many emails we receive about it).

We are making them somewhat steadily - but they require quite a lot of Titanium to produce each one ...AND they take quite a long time to make (this is mostly due to having to get the outside as smooth as possible during the CNC machining process so we can then put a polished finish on it).

It takes 8mm thick material and, as of right now, I have run out of this thickness. I have more on the way - but it's going to be a while.

Someone suggested in the comments of Facebook the other day that we make a Mini Atom - and it's something I had actually never though about.

So I thought it was a good time to design, prototype and make one (since we could almost certainly make it from slightly thinner material).

First thing was to make a rough 3D-printed version purely to get the size right first. When you scale a 3D object down, say, 10% ...it never feels like it's just 10% smaller. It always feels like it's at least 30% smaller. It's weird.

We made a first design (LEFT) - but it felt too small - so we then made the second design (RIGHT):

The one on the right is just 15% smaller than the original Atom - but it feels small than that (15% doesn't sound a lot ...but it feels a lot).

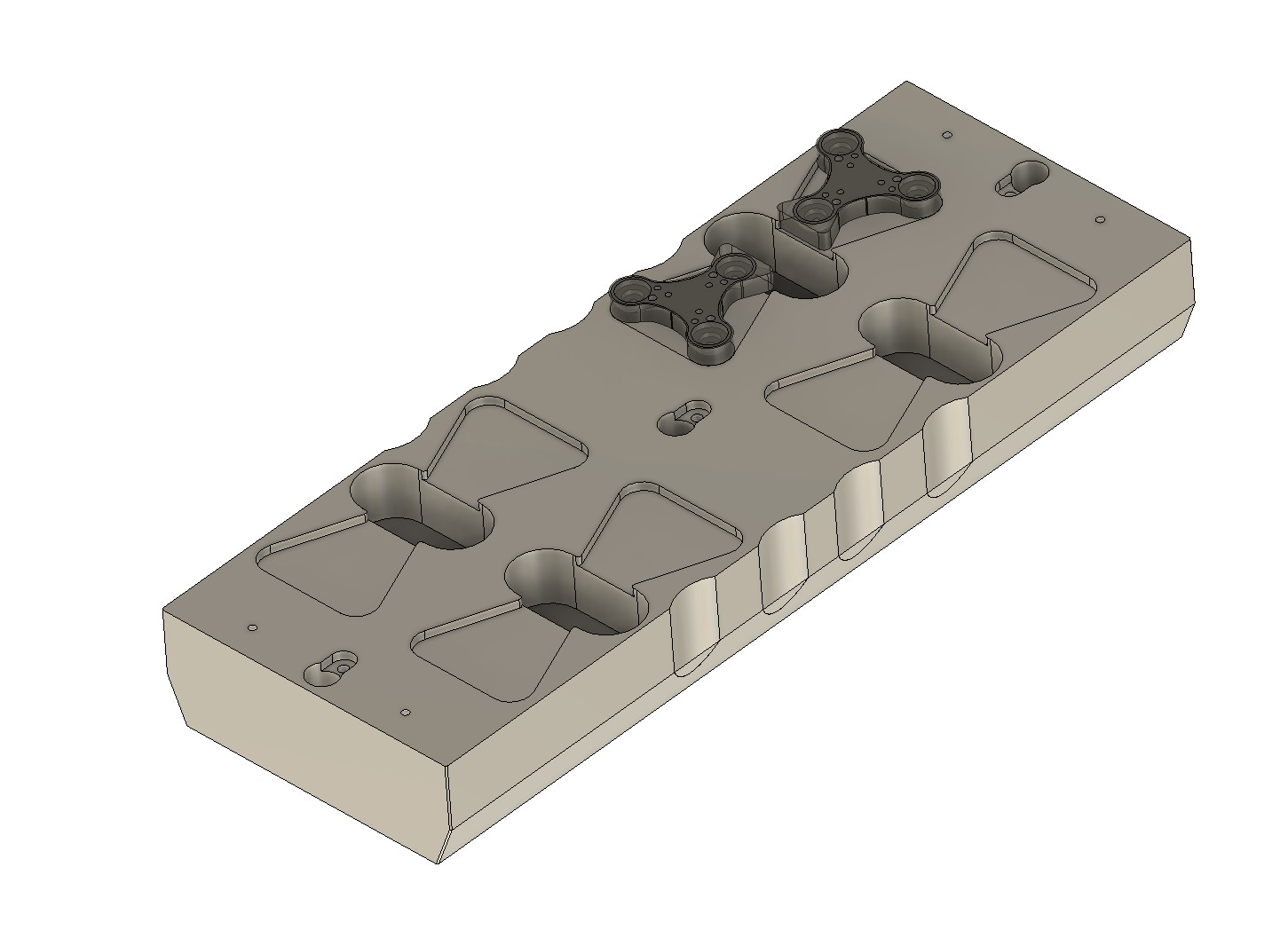

We are planning to start making the CNC fixtures today - here's what they will look like:

Since this is essentially a smaller version of a product we already know works - it should (hopefully!) work without too many tweaks or adjustments.

It's not an exact scaled-down version - we actually had to create it from scratch (scaling it in different ways to allow for magnet-size, screw-position, and other things).

I'm not sure when the first one will be ready - I'm hoping within a couple of weeks.

UPDATE: Actually, possibly sooner! Turns out we're onto it and started machining the fixtures this morning

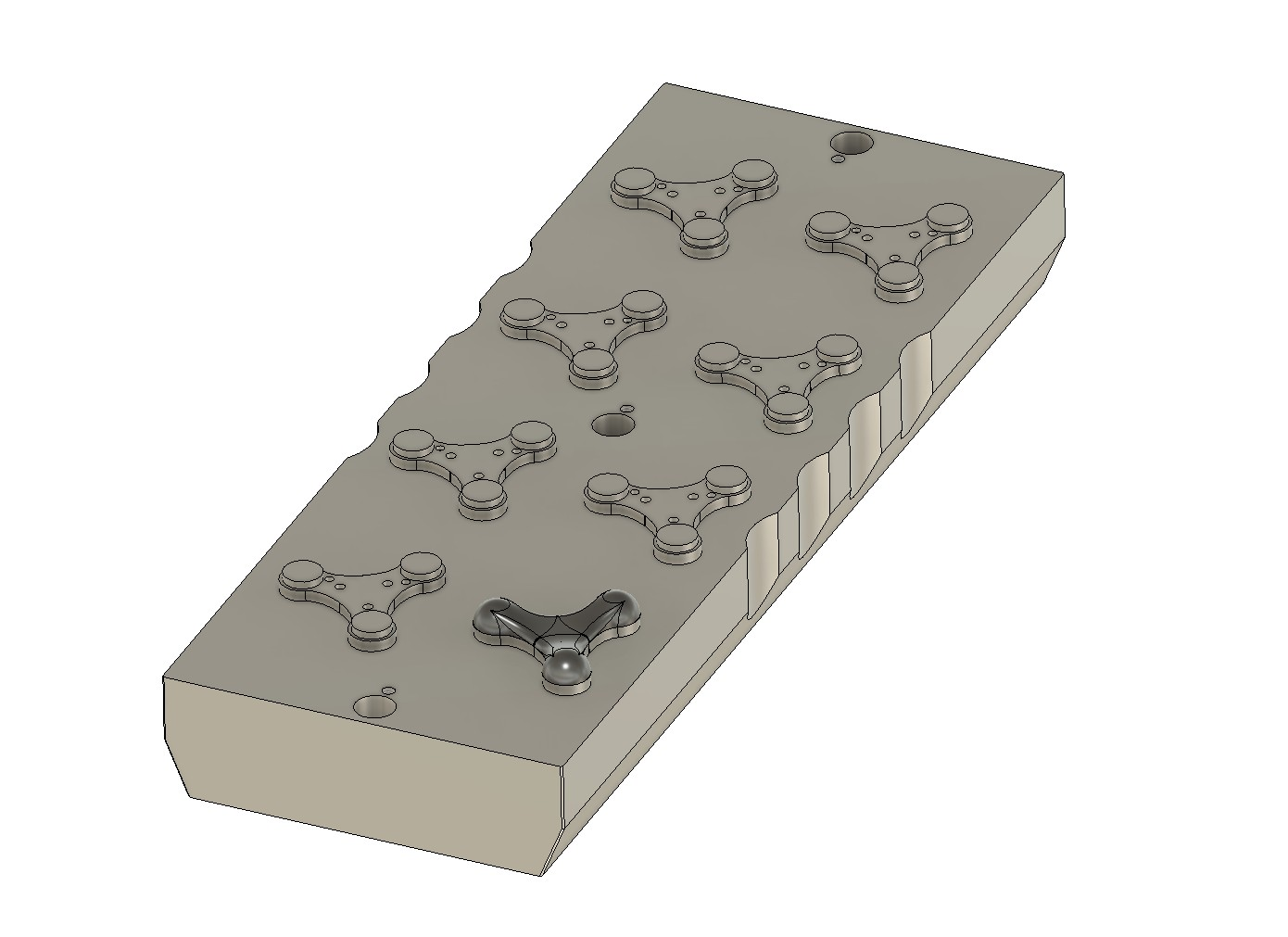

Here's the rear of one in the machine:

And here's the other one:

Various Wear Plate Styles (behind the scenes)

Here's a super-short video of how we rack slider Wear Plates as they are being produced.

In the video above you'll see "Pom". SkellyHex" and "Skelly" plates. Also, the "Pom" plate is short for Pomegranate (because I thought it looked like the inside of that particular fruit).

We design and 3D print the mini racks/holders you see in this video: