"Who Else Wants Access To This High-End And

Customizable Titanium 'Flipper' Knife?"

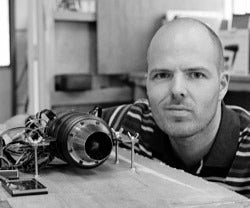

From: Magnus Macdonald, MagnusX.com

Dear Friend,

If you like high-end knives and want to be part of something big, then you're on the right page!

I'm about to reveal to you the details of a high-end flipper knife called: "Project ZERO"

Before I continue...

Just to make sure I'm not wasting your time there are a few things you need to know about "Project ZERO" :

#1 - This project is not some mass-produced, factory made sub-$500 knife. No. If you want some 'big name' stamped on your knife, then you're going to be disappointed (this is more of a bespoke/custom project)

#2 - "Project ZERO" is currently at the prototype/development stage and so all images on this page are screenshots directly from my CAD/Design software

#3 - The "Project ZERO" knife is around 85% developed and you're going to get a behind-the-curtain, front seat view of the creation of this knife via exclusive photo, video and blog updates

In other words...

Not only are you getting access to a never-before-released high-end-knife... but you're getting to be part of the development and story of "Project ZERO".

Minimalist Design

Fully Titanium

Fully Machined Pocket-Clip

Pocketed Scales

Dimensions

Blade Size

Blade Style and Grind

Choose Your Blade Steel

Blade Heat-Treatment and Sharpening

Timascus™/ Moku-Ti™ Options

Framelock

Bearings

Surface Finishing

Unique Serial Number

Customization

YES! I'm Ready To Order My

Project ZERO™ High-End

Titanium Flipper Knife

A couple of IMPORTANT things:

#1 - Please check your local knife laws in the country you live. Any issues you have with customs in your country is something I have no control over unfortunately.

#2 - The final version of the "Project ZERO" knife is likely to be slightly different to what is shown in the images above - but you will be following along as the design is tweaked upon and the final design produced.

One last thing...

This is your only chance to be part of a project like this (doubt I will ever offer this again). Clicking the 'Add To Cart' button RIGHT NOW is the only way I can guarantee you will be part of "Project ZERO".

To impossibly high standards,

Magnus

FAQs

MagnusX.com © 2021, All Rights Reserved.

Mount Maunganui, New Zealand