(Scroll to bottom...)

"They Laughed When I Said I was Making A Knife

- Until I Showed Them This..."

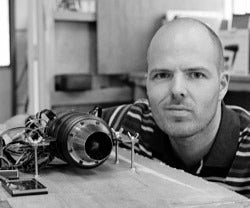

From: Magnus Macdonald,

In case you’re not too familiar with knives… ‘scales’ is the term used for what is essentially the sides of the handle.

From the start I pretty much knew, to be light-weight, the scales needed to be made from Titanium (Grade 5 of course!).

Blade Steel

Friction Folder

Compact and Rock-Solid design

I’m not scared to admit this:

I am hard on knives. Actually, I am DAMN HARD on knives. I use them as pry-bars and levers. I'll use the back of the handle as a hammer. I’ll often chip the blade from time to time too.

Now, because of this, I’ve built the Flixx™ from the ground up to be rock-solid. It is compact – but it’s also got a ton of grunt!

If you've not picked up on it already - I'm holding almost nothing back in the designing and making of this knife. The knife uses the best materials and in the design and manufacture it enjoys an incredible attention to detail.

And, in line with that...

EVERY piece of hardware on the knife will be made from Grade 5 Titanium.

The front pivot-screw, the rear back-spacer screws and the back-spacer itself ...all titanium. Like I said... this is a no-holds-barred and nothing-held-back knife.

And the other thing...

I did not want to make the screws a “feature” on this knife. The screws are simple, flush-sitting and totally unobtrusive.

This is a no-nonsense, clean-looking knife and so the hardware had to be this way too.

Flat Grind Blade

The Flixx™ has a flat grind on the main bevel. This is a simple, classic grind which is perfect for what I wanted to achieve with this knife.

The blade design on the Flixx™ is a classic “drop-point”… because it just works so damn well.

However, I’ve given the blade more ‘depth’ than you would typically find on a blade of this style. Together with the handle shape this maintains the robust and strong design.

I’ll be honest here…

I’ve not settled on the final thickness of the blade because, as I mentioned earlier, I'm still undecided on the exact steel we're going to use.

But for now, I can confirm the blade will be around 3.5mm (or 0.14") thick (give or take a little). This results in a rock-solid blade that, if you’re like me, you can use and abuse!

In case you’re not familiar …the ‘choil’ is typically known as the area between the blade and the handle.

What I’ve done on the Flixx™ is design a finger choil (this is the kind of super-functional thing my obsessive-compulsive personality loves!)

Not only does the finger choil protect your fingers from the blade… but it helps you grip the handle better on a small-form knife like this (once you get the knife in your hands you'll feel exactly why!).

The Flixx™ will run on phosphor bronze washers - because they are, quite simply, the best option for this knife.

These washers are super-smooth to use and do not compress (unlike something such as nylon).

Matte Finish

Both the blade and scales of the Flixx™ will be finished with my – now famous – matte surface finish. This finish is bright, smooth, and wears well.

And it gets even better:

Because I "just can't help myself" ...the hardware for the knife will also have the same surface finished processes done (yes, I am fairly obsessive about this kind of stuff and will be surface finishing each individual screw!).

Contoured Scales

The blade length is 50mm (or around 2").

Thumb Chamfers

On the pocket clip I’ve really tested and tweaked the design for optimal functionality for you. One of the main features is the large chamfers on the pocket-clip to aid your thumb in opening the knife.

"Disappearing" Pocket Clip

When the knife is in use the pocket-clip “disappears” into the body of the knife.

The knife does not ‘lock’ (because it is a friction folder). However, because your hand covers the top of the handle, the knife cannot close when in use as your hand holds the clip in place.

Fully CNC Machined In-house

Unlike most other knives… 100% of this knife will be CNC machined. Yes, even the blade (no "old school" grinding on this knife).

This results in each knife coming out just as I designed it… down to 0.001mm (or less than 0.0001” if you're more familiar with the imperial system).

The design and prototyping of the Flixx™ was done entirely by me on my CNC-Milling Machine.

And, likewise, we will be doing the production in house too.

Click Below To Order The

"BLACK - Limited Edition" Flixx™ Knife

To impossibly high standards,

Magnus

MagnusX.com © 2019, All Rights Reserved.

Mount Maunganui, New Zealand